NEWSLETTER N° 2 | 06 – 2017

Welcome back to the Newsletter of the Life HEROTile Project, which has come to its second edition, after the N° 1 published in February. The Newsletter aims at informing people about the state of the art of the project and gives to the actors involved in the project the opportunity to share their views and to get some visibility for the achieved results.

To subscribe to the Life HEROTile Newsletter and to be always updated regarding the developments of the project, please visit the dedicated page of the website of the project.

However, the Newsletter is not the only way to communicate and disseminate the results and the status of the project: if you are a fan of Social Networks do not forget to follow us on Facebook, Twitter and LinkedIn!

Meet Life HEROTile Partners! Interview with Christian Pohl – Director, Monier Technical Centre Germany and UK

Meet Life HEROTile Partners! Interview with Christian Pohl – Director, Monier Technical Centre Germany and UK

The Monier Technical Centre is THE research and development centre in the Braas Monier Building Group, servicing the Group´s operations in more than 30 countries worldwide. How important is product quality and how do you ensure it?

Well, quality as well as innovation is a decisive part of our companies´ DNA. We produce and supply roofing products, systems and services with the aim to meet, and where possible exceed, the expectations of our customers. That is true for the entire organization, be it the Technical Centre where we have long-term experience or any business unit around the globe. We all strive to improve quality through learning, benchmarking, knowledge sharing and innovation in all our activities and processes. We do not do this out of the blue – it is defined in our group-wide quality management system. It enables us to set clearly defined quality targets, and measure our progress against these at regular intervals.

But that alone is not enough. Regarding the Technical Centre’s role we look into the quality and performance of our systems from different angles. We ensure this approach by having the right people on board – from material scientists over product designers to engineers. Highly experienced people who not only work together with internal local marketing and product development but also with external specialists and equipment manufacturers.

Secondly we take care that we have state-of-the-art testing equipment in place, using it thoroughly during product development. Before manufacture of any new product begins, an extensive programme of trials, testing and implementation is carried out. These trials can take place at a production location or at the Technical Centre’s own pilot manufacturing facilities.

Secondly we take care that we have state-of-the-art testing equipment in place, using it thoroughly during product development. Before manufacture of any new product begins, an extensive programme of trials, testing and implementation is carried out. These trials can take place at a production location or at the Technical Centre’s own pilot manufacturing facilities.

And beside others we support the Braas Monier’s business units w orldwide by validating raw material resources, defining production processes and assuring that state-of-the-art and standardised technology is being used for their production facilities. Through the systematic implementation of process control guidelines and standards, the operation of Braas Monier’s plants is assured to be carried out according to the highest standards of safety, quality and continuous improvements.

orldwide by validating raw material resources, defining production processes and assuring that state-of-the-art and standardised technology is being used for their production facilities. Through the systematic implementation of process control guidelines and standards, the operation of Braas Monier’s plants is assured to be carried out according to the highest standards of safety, quality and continuous improvements.

Apart from CE labeling are there other proofs/certifications you give to a good quality product?

As I said – superior performance is a major criterion for the success of our roofing materials. Before a new product is launched on the market we carry out extensive tests to ensure that it meets the standards and our high internal quality requirements and provides reliable protection under many different climatic conditions. Our defined product validation process is only one internal standard ensuring that we meet high quality levels. That is our part. Applying for and getting the CE label is a given requirement for us and the business units, which are launching the product.

Let me give you another example. When you buy a roof you want it to offer protection against the elements for decades. Our performance tests are the basis for long-term materials guarantees for quality roofing materials resistant to all weathers, such as a 30-year permeability guarantee for most of our clay tiles that we give, for example, in Italy.

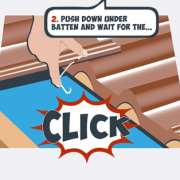

Through interaction with roofers and architects we make sure that our products also meet the needs of our customers not only in terms of functionality or beauty on the roof but also in terms of ease of laying and handling. A lot of awards and prizes in nearly every country we are operating in, give proof that especially our customers appreciate our products and services. Regularly we are among or even THE preferred brand of our customers in Poland, Czech Republic, Malaysia, or Germany just to name a few. Some of our products, like Innofix, the tool-free tile clip of Redland in the UK, the ultra-lig

Through interaction with roofers and architects we make sure that our products also meet the needs of our customers not only in terms of functionality or beauty on the roof but also in terms of ease of laying and handling. A lot of awards and prizes in nearly every country we are operating in, give proof that especially our customers appreciate our products and services. Regularly we are among or even THE preferred brand of our customers in Poland, Czech Republic, Malaysia, or Germany just to name a few. Some of our products, like Innofix, the tool-free tile clip of Redland in the UK, the ultra-lig ht Clima Comfort insulation panels of Monier France or the tile “Classic Protector PLUS” sold by our colleagues at Bramac Czech Republic with its high performance surface, received awards from home-owners, roofers and architects alike. We believe that this is the best certification we could get – because it comes from our customers.

ht Clima Comfort insulation panels of Monier France or the tile “Classic Protector PLUS” sold by our colleagues at Bramac Czech Republic with its high performance surface, received awards from home-owners, roofers and architects alike. We believe that this is the best certification we could get – because it comes from our customers.

The wind tunnel was used to compare existing clay tile designs with the two newly developed profiles in the context of the LHT project. What exactly did you test with the wind tunnel and in what way did the results contribute to the overall project?

The wind tunnel was used to compare existing clay tile designs with the two newly developed profiles in the context of the LHT project. What exactly did you test with the wind tunnel and in what way did the results contribute to the overall project?

Let me first drop some words on the wind tunnel which was also involved in the testing of the tile models in the context of our joint LifeHeroTile project. Our wind tunnel can simulate wind and rain conditions found in a wide range of different climate zones worldwide. The simulations include situations which typically occur only once every 50 years. The wind tunnel testing is based on weather data which we have been collecting continuously in many countries for decades. Usually four representative scenarios per climate zone are simulated. Wind, the amount of rainfall and roof pitch are only some of the parameters which are specifically targeted during the tests. Experienced roofing specialists observe and analyse the behaviour of the roofing materials in the wind tunnel.

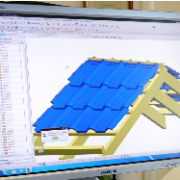

Additionally we have studied the performance of roofs in all kinds of weather and climate conditions, both in real life buildings and in our laboratory. This knowledge has been used to develop a software capable of predicting the energy performance and condensation risk of virtually any roof construction in any climate. Application areas of this MRPS (Monier Roof Physics Software) are, among others, the design of Braas Monier Cool Roof systems for hot climates, the design and optimisation of new ventilation products, the study of new concepts for roof constructions, the study of the influence of air and wind tightness and guidance for the development of national and international standards.

Now coming back to our LHT project. Here the wind tunnel was used initially to test the driving rain performance of the two reference tile profiles, a Portuguese and a Marseille. These tiles were representative of typical tile designs that are commercially available and were to be used as the basis against which to judge the newly-developed LHT designs. There were 10 conceptual designs for each tile profile and these were whittled down to the 3 designs that were considered to be the best options by the LHT partners, using a number of design, industrial and market-driven criteria.

Then those 6 tiles (3 Portuguese + 3 Marseille) were realized as sets of gypsum prototypes and tested in the wind tunnel. Finally,  the relative driving rain performance of the prototypes against the reference tiles – in addition to the air-openness measurements also made by Technical Centre – was used to select the two LHT designs that will be put into production.

the relative driving rain performance of the prototypes against the reference tiles – in addition to the air-openness measurements also made by Technical Centre – was used to select the two LHT designs that will be put into production.

Of course, these tests on idealised prototypes cannot guarantee the performance of real production tiles. There is a lot of work ahead of us still. Product development starts from prototypes, but the path which leads to the final product requires many more steps, Therefore the final result may be different from the prototype performance results.

Life HEROTile Project has been presented at the LIFE Platform Meeting, which took place on April, 11th in Sassuolo, in the charming location of the headquarter of Confindustria Ceramica. The event had the goal to present the experience of the projects aimed at improving the environmental sustainability of ceramic and tiles industry, which are financed within the framework of the LIFE Programme and was attended by 47 participants.

Life HEROTile Project has been presented at the LIFE Platform Meeting, which took place on April, 11th in Sassuolo, in the charming location of the headquarter of Confindustria Ceramica. The event had the goal to present the experience of the projects aimed at improving the environmental sustainability of ceramic and tiles industry, which are financed within the framework of the LIFE Programme and was attended by 47 participants.

The event was organized by Federazione Confindustria Ceramica e Laterizi, in collaboration with Centro Ceramico di Bologna e the National Contact Point LIFE, with the patronage of the Ministry of the Environment. The scope of the LIFE Platform Meeting was to create an opportunity to share the best practices in the ceramic sector. Besides the intervention by the LIFE Institutions (National Contact Point LIFE, EASME e LIFE External Monitoring Team – NEEMO), nine projects have been presented. One of these projects was indeed Life HEROTile, which was presented by the Coordinator of the project, Mario Cunial, who held a speech on how to improve the energy efficiency in building cooling thanks to a new optimized shape of the roof tiles that lead to a better above sheathing ventilation.

The event had a great impact on the media and particularly it was mentioned in the following channels:

- Newsletter n.2 of the Ministry of Environment dedicated to the platform of knowledges;

- Website of the LIFE Programme;

- Website of Casa e Clima;

- Website of Centro Ceramico;

- Website of ACER;

- Imprese Edili News;

- Sassuolo Oggi;

- ANDIL Website.

Click here to see some pictures of the event!

On June 22nd there will be the Mid-Term Conference of the Life HEROTile Project, which will mark a very important moment for the project lifetime, as it will present what has been done so far, it will sum up the main achieved results and lessons learnt and it will illustrate what will be the next actions to be undertaken by the beneficiaries, in order to reach the expected goal.

The Life HEROTile Mid-Term Conference will take place in Nice, at the Hotel Le Royal, from h. 17.30 to h. 19.00. The Conference is organized within the Tiles and Bricks Europe (TBE) annual Congress, which this year will be hosted by the French Federation of Roof Tiles and Bricks.

The programme will start with a welcome address and introduction by Mr. Renaud Batier, Director General of Ceramie-Unie, the European Ceramic Industry Association. It will continue with a presentation of the project mid-term results and the main benefits of the ventilated roofs, by Mr. Mario Cunial, Coordinator of the Life HEROTile project and Vice President of ANDIL, the Italian Association of tiles and clay bricks producers.

The Conference will end with a question and answer session and conclusions.

The objective of the Mid-Term Conference, besides spreading the news about the ongoing activities of the project, is also to inform the European policy-makers about the opportunities in the field of energy efficiency that this project presents and, therefore, to make them aware about the potential of the new tiles developed thanks to the project, in a view to take into consideration these optimized and innovative tiles in the future EU policy-making activities.

To register: [email protected]!